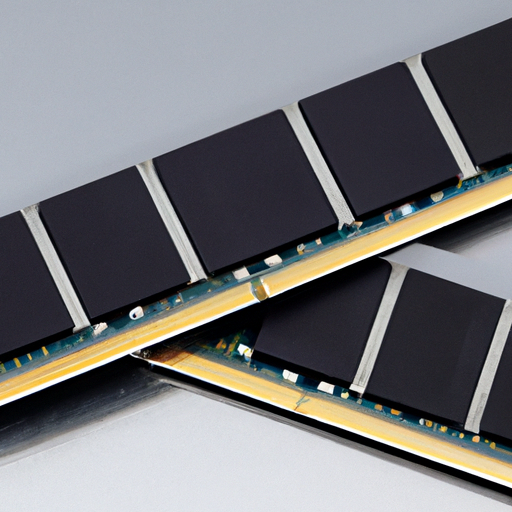

Memory connectors are an essential component in electronic devices, allowing for the transfer of data between the memory module and the motherboard. These connectors are crucial for the proper functioning of devices such as computers, smartphones, and tablets. The production process of memory connectors is a complex and intricate one, involving several steps to ensure the highest quality and reliability of the final product.

1. Design and Development: The first step in the production process of memory connectors is the design and development phase. This involves creating a detailed blueprint of the connector, including its dimensions, materials, and specifications. Engineers and designers work together to come up with a design that meets the requirements of the device it will be used in.

2. Material Selection: Once the design is finalized, the next step is to select the materials that will be used to manufacture the memory connector. The materials chosen must be durable, conductive, and resistant to corrosion. Common materials used in memory connectors include copper, gold, and various types of plastics.

3. Tooling and Molding: After the materials have been selected, the next step is to create the tooling and molds that will be used to manufacture the memory connectors. This involves using specialized equipment and machinery to create the precise shapes and sizes required for the connectors.

4. Injection Molding: Injection molding is a common manufacturing process used to produce memory connectors. In this process, molten material is injected into a mold cavity, where it cools and solidifies to form the desired shape. Injection molding is a cost-effective and efficient way to produce large quantities of memory connectors.

5. Plating: Once the memory connectors have been molded, they are plated with a thin layer of metal to improve their conductivity and corrosion resistance. Common plating materials include gold, silver, and nickel. The plating process is essential for ensuring the reliability and longevity of the connectors.

6. Quality Control: Throughout the production process, quality control measures are implemented to ensure that the memory connectors meet the required specifications and standards. This involves testing the connectors for conductivity, durability, and compatibility with the devices they will be used in.

7. Packaging and Shipping: Once the memory connectors have passed quality control, they are packaged and prepared for shipping to customers. The connectors are typically packaged in trays or reels to protect them during transit.

Overall, the production process of memory connectors is a complex and multi-step process that requires precision, attention to detail, and quality control measures. By following these steps, manufacturers can produce high-quality memory connectors that meet the demands of today's electronic devices.